Au88Ge12 Solder Preforms

Au88Ge12 Solder PreformsAu88Ge12 has the advantages of low vapor pressure, low base resistance, low melting temperature etc.

Au88Ge12 Solder PreformsAu88Ge12 has the advantages of low vapor pressure, low base resistance, low melting temperature etc.

Au88Ge12 Solder Preforms

Introduction

Au88Ge12 has the advantages of low vapor pressure, low base resistance, low melting temperature, good adhesion to the substrate, high conductivity and thermal conductivity. As an eutectic solder, it has been widely used in chip welding and packaging. It is commonly used in welding of electronic products, vacuum devices, high temperature welding and welding of some special materials. It is especially suitable for brazing devices used in high vacuum systems, such as gold plating, silver-plated aluminium, Ag, Cu, Ni and Kovar alloys, etc. in atmosphere or H2 gas furnace.

Basic Properties

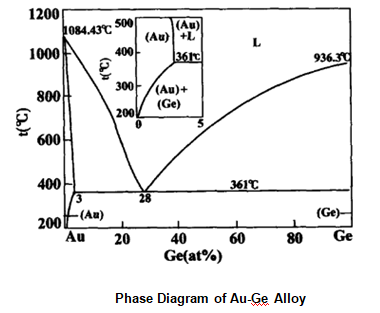

Au-Ge alloy is eutectic alloy with eutectic point composition of 12wt%Ge and eutectic temperature of 356℃. As follows,

Au-Ge alloys have properties suitable for use as packaging materials.

Low sealing temperature. The melting point of Au-Ge alloy (eutectic alloy) is 356℃. Brazing temperature is 380 ~ 400℃.

Low sealing temperature. The melting point of Au-Ge alloy (eutectic alloy) is 356℃. Brazing temperature is 380 ~ 400℃.

Good wettability and corrosion resistance. The alloy contains 88 wt% Au, which is close to the composition of the gold plating layer. Therefore, the immersion degree of the very thin coating by diffusion is very low.

Good wettability and corrosion resistance. The alloy contains 88 wt% Au, which is close to the composition of the gold plating layer. Therefore, the immersion degree of the very thin coating by diffusion is very low.

High tensile strength. The tensile strength at room temperature is about 220 MPa, which is equivalent to that of some high temperature solders, but the whole brazing process is completed at a much lower temperature.

High tensile strength. The tensile strength at room temperature is about 220 MPa, which is equivalent to that of some high temperature solders, but the whole brazing process is completed at a much lower temperature.

Low thermal expansion coefficient. In the process of assembly and service of electronic devices, the mismatch of CTE is an important cause of packaging failure. Therefore, the thermal expansion coefficient of electronic packaging materials must be low enough to match the characteristics of interconnected silicon components. The CTE of Au-Ge alloy is lower than that of AuSn and AuSi which are also used as electronic packaging.

Low thermal expansion coefficient. In the process of assembly and service of electronic devices, the mismatch of CTE is an important cause of packaging failure. Therefore, the thermal expansion coefficient of electronic packaging materials must be low enough to match the characteristics of interconnected silicon components. The CTE of Au-Ge alloy is lower than that of AuSn and AuSi which are also used as electronic packaging.

Good thermal conductivity. Au-Ge alloys can provide mechanical support for semiconductor chips, connect current circuits of semiconductor chips, and dissipate heat from semiconductor chips in microelectronic devices.

Good thermal conductivity. Au-Ge alloys can provide mechanical support for semiconductor chips, connect current circuits of semiconductor chips, and dissipate heat from semiconductor chips in microelectronic devices.

Lower vapor pressure.

Lower vapor pressure.

It has better corrosion resistance and oxidation resistance than silver-based alloys.

It has better corrosion resistance and oxidation resistance than silver-based alloys.

Good dispersibility.

Good dispersibility.

High temperature stability is good. In general, brittle phase is not formed during welding, so the welding strength is high.

High temperature stability is good. In general, brittle phase is not formed during welding, so the welding strength is high.