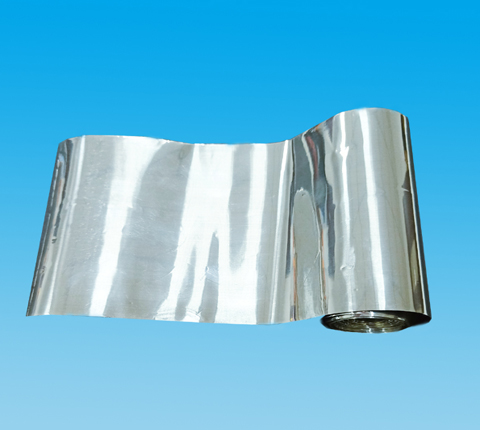

Indium Alloy Solder Preforms

Indium Base Solder Preforms

Indium Base Solder Preforms

Indium Alloy Solder Preforms

Indium Base Solder Preforms includes In100, In97Ag3, In66Sn34, In52Sn48, In50Sn50, etc., which has good ductility, malleability and ultra-low temperature sealing property. Due to its low metling point, it can be combined with Sn, Pb, Ag and other elements to form a series of eutectic solder with low melting point.

Indium based alloy solder in alkaline medium has high corrosion resistance, the metal and nonmetal have good wetting ability, the formation of solder joints has advantages of high plassticity, low resistance, and can be used in the matching of different thermal expansion coefficient materials packaging, especially for ceramics, glass and other nonmetal has good wettability, has become one of the main special solder microelectronics packaging.

Application:

1.Cryogenic seal——Indium remains ductile and malleable at temperatures below -150℃.

2.To weld or fuse——Melting temperature:5℃~310℃.

3.High-end device cooling——The operating temperature can be reduced by up to 10℃.

Characteristic:

1.High thermal conductivity(86W/mK at 85℃)

2.It is ductile and malleable and can be deformed with moderate pressure to fill in the small uneven gap between two mating pieces.

3.Some indium—containing alloys have a melting point below 180℃, making them ideal for multiple welds or those requiring low reflux temperatures.

4.Its steam pressure is low, suitable for high vacuum welding.

5.Normal sealing operations require sealing between passages or other uneven surfaces. Indium does not require reflux to compensate for these deficiencies.

Attention:

The cleanliness of indium is extremely important in sealing applications. Indium can be self-passivated, will form on the surface thickness of 80-100 angstrom oxide. If the oxide is not completely removed, it can become a source of air leakage when compressed within the seal.